Erase pathogens and allergens to make

Your air and surfaces 99.99% pure

Using hydroxyl generator technology, you can harness the disinfecting power of the sun indoors. This system safely, effectively cleanses both air and surfaces in any size building. It’s time for clean you can count on, so good health can be part of your business as usual.

Hydroxyl Generators

Hydroxyl Generators: Safe Indoor Air, Nature’s Way

Take a long, deep breath. What was in the air you just inhaled? In addition to oxygen, aromas and other substances, our air is also host to dust particles, VOCs (volatile organic compounds), mold, bacteria, and viruses. We breathe up to 23,000 times per day, taking in both oxygen and toxins. If our air is contaminated with pathogens, it can bring on both acute and chronic illnesses. The quality of the air we breathe goes a long way in supporting our overall health. With Americans spending an average of 90% of their time indoors, indoor air quality is of critical importance. Poor quality air inside buildings can trigger asthma and allergy attacks, headaches, nausea, and flu-like symptoms as well as spreading bacteria and viruses, including COVID-19. Fortunately, this problem has solutions. Many different systems have been developed to combat indoor air pollution. Some of them create issues of their own, as we will discuss later. How do we clean our air in a way that is effective and safe for both humans and the environment? When we look to nature for answers, we find that the solution is all around us every time we step outside on a sunny day.

Residential & Commercial Buildings

Schools & Churches

Health Care Facilities

Warehouses

Restaurants & Small Businesses

Sporting Events & Shopping Centers

Hydroxyls: Nature’s Disinfectant

You may have heard before that sunlight is a natural disinfectant. Sunlight is only part of that equation, however. To understand the power of the sun to clean, we need to understand hydroxyls.

A Chain Reaction

Lorem ipsum. When the sun’s ultraviolet rays react with oxygen and water vapor, HO• molecules are created called hydroxyl radicals. The hydroxyls then react with VOCs to create organic oxidants, powerful sanitizing agents. This begins a chain reaction of those organic oxidants repeatedly decomposing more VOCs and their by-products, creating more organic oxidants, which in turn react with other VOCs, and so on — without the dangers of ozone.

A Microscopic Cleanup Crew

The organic oxidants created by hydroxyls are toxin killing machines. In addition to eating up the VOCs (both natural and human-made) that can make people sick, they also destroy bacteria, viruses, and mold. When organic oxidants encounter these pathogens, they dissolve their cell walls in a process called lysis. Bacteria, mold, and viruses are eradicated as their cell walls are destroyed.

Shedding Light on Pathogens

This process of hydroxyl generation is why sunlight is a natural disinfectant and why it’s much harder for microbes to live and spread in the presence of UV light. It’s nature’s perfect answer to toxin and pathogen control. However, hydroxyls are not created indoors. How do we harness that pure, cleansing power and use it where we are spending most of our time?

What is a Hydroxyl Generator?

While the sun and the natural environment may be the world’s largest hydroxyl generating source, that doesn’t help us when we’re inside. That’s why we have learned how to re-create nature’s perfect sanitizing action in the form of indoor hydroxyl generators. By using the same process that happens outdoors, we can invite the beneficial cleaning effects into our offices, homes, schools, hospitals, warehouses, and more.

Re-Creating Sunshine

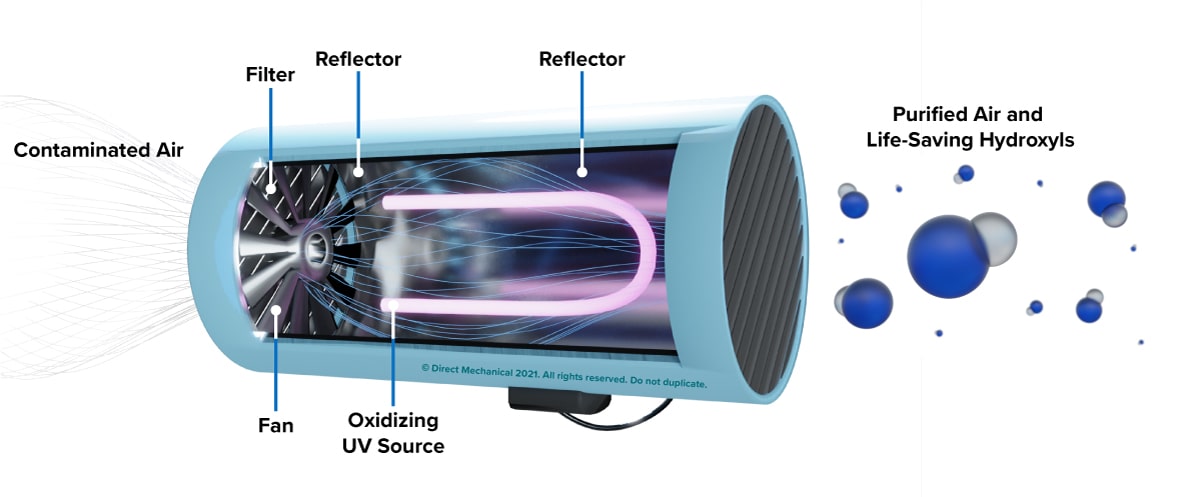

Hydroxyl-based air purification systems work by circulating contaminated air through quartz optics chambers. In the chamber, the air and water vapor are irradiated with ultraviolet light, creating hydroxyls. The purified air and hydroxyls exit the hydroxyl generator. They are pushed out into the surrounding area, where the hydroxyls begin to interact with VOCs in the air, creating those air-scrubbing organic oxides.

Continuous Cleaning, Inside and Out

A distinct benefit using a hydroxyl machine is that they clean air both inside the device and outside, as the organic oxides continue their cascade of devouring VOCs and reproducing themselves. Because of this effect, the oxides continue cleaning throughout the air as they come into contact with both hard and soft surfaces. This makes hydroxyl generators not just air purifiers but also surface cleaners.

Hydroxyl generators are able to mimic the way nature cleans by implementing technology and human ingenuity. But as with any cleaning solution, we must evaluate their overall viability: effectiveness, safety, and other alternatives. Let’s review each of these concerns in depth.

How Effective are Hydroxyl Generators?

It’s encouraging to hear that we’re able to replicate the cleansing energy of the sun indoors, but it’s not enough to understand the process in theory. We must also put hydroxyl generators to the test scientifically. Here’s how the numbers stack up when hydroxyl generators were tested in controlled environments for their ability to destroy harmful microbes.

Powerful Virus Control – When tested against MS2 virus (an aerosolized coronavirus simulant) and PhiX174 (an aerosolized simulant for smallpox), the hydroxyl generator killed 99% of the viruses in the air in 15 to 20 minutes. It eliminated 99.99% of the virus in 30-40 minutes for the coronavirus and 35-50 minutes for the smallpox simulant.

Neutralizing COVID-19 – In a later study, hydroxyl generators were specifically tested against COVID-19, or SARS-CoV-2. At the 20-minute sampling point, 99% of the virus had been eliminated from the air. At 80 minutes, the hydroxyl machine had killed 99.98% of the aerosolized virus. Wiping Out Bacteria – When it comes to bacteria and mold, hydroxyl generators prove to be just as effective as they are against viruses. Both gram-positive bacteria in the form of Staphylococcus E. (staph) and gram-negative bacteria in the form of E. herbicola were no match for our hydroxyl generator. Both forms of aerosolized bacteria were 99% eliminated in 20-25 minutes. The hydroxyl machine effects killed 99.99% of the bacteria in 35 minutes for gram-negative and 45 minutes for gram-positive.

Erasing Mold – Airborne black mold (Aspergillus Niger), which can cause mild to severe lung infections and allergic reactions, was 99% destroyed in 15 to 20 minutes and 99.99% neutralized in 40 minutes.

Shown Effective Against COVID-19. In the study specific to COVID-19, surfaces contaminated with the coronavirus showed a reduction of 99% by 60 minutes after being in an area receiving hydroxyl generator treatment. Affected surfaces continued to show a 99.999% decline in the virus up to the 180-minute marker, where COVID-19 was no longer detectable. While the virus is still being studied, researchers have suggested that SARS-CoV-2 can otherwise last up to 28 days on hard, non-porous surfaces such as glass and steel.

Flu-Fighting Power. When tested against Influenza A, spaces being sanitized with hydroxyl machine power demonstrated the elimination of 99.99% of the virus on stainless steel and cotton surface

Hydroxyl machine treated facilities can expect to enjoy a significant improvement in air quality and a reduction of viral and bacterial infections among occupants. By bringing sunlight’s power indoors, we are creating cleaner, safer environments, helping everyone stay well. Now that we’ve covered the effectiveness of hydroxyl machine technology, let’s talk about overall safety.

How Safe are Hydroxyl Generators?

It’s not enough for hydroxyl generators to be effective; they also need to be safe. The compounds created by hydroxyl generators, hydroxyl radicals and organic oxidants, are elements to which humans and animals are naturally accustomed. We are constantly exposed to these molecules every time we set foot outdoors on a sunny day.

Just Like Being Outside

The concentration levels of organic oxidants including ozone produced by hydroxyl generators are also the same as those found in nature, less than 50 PPB (parts per billion). So living or working in an environment sanitized by a hydroxyl generator exposes humans to the same levels as if they were outdoors. No scientific studies have found any safety concerns with atmospheric hydroxyls or organic oxidants at their natural levels.

No Adverse Impact Found

Independent toxicology lab testing over a 13-week period also showed no adverse effects, unlike ozone. Rodent test subjects were exposed to hydroxyl generator purified air continuously for the entire study period at a level three times higher th an those in a typical treatment environment. None of the rats exhibited any adverse events and showed no difference compared to the control group.

No Harm to Materials

Hydroxyl generators are not only safe for people and animals, but also for surfaces, materials and objects within the sanitized zone. Some other forms of air purification are not safe to be used for occupied areas and can damage non-living items. Hydroxyl generators do not cause bleaching or any other damage to equipment, supplies or electronics.

Made in America for 15 Years

Our hydroxyl generators have been on the market for fifteen years and are proudly manufactured in the United States. We have models that have been reviewed and approved by the FDA for use in medical facilities. Safety is our top priority, and we stand behind our hydroxyl machine quality.

Ready to breathe with confidence?

Contact us today for a consultation and see how hydroxyl generators can level up your organization’s health, no matter how large or small.

How Hydroxyl Generators Stack Up to the Alternatives

Hydroxyl generators are not the only air or surface purification systems available. To understand the true benefits offered by hydroxyl generators, we should also be familiar with the next best options. What are the alternatives to hydroxyl generators, and what are the pros and cons?

Filtration/Adsorption and Ionization

Air filtration and adsorption removes dust and particulate matter from the air along with low levels of VOCs. Adsorption is a physical attraction of gasses or vapors to a surface. If the device includes a HEPA filter, it can remove 99.97% of airborne particles down to .3 microns. This is sufficient for filtering out bacteria and mold from the air, but many viruses are smaller than .3 microns, including COVID-19. Ionization processes charge particulates both positively and negatively which increases the level of filtration. These types of systems are safe for occupied spaces, but do not filter out higher levels of VOCs, sanitize surfaces or eliminate smaller viruses the way a hydroxyl machine does. They also require frequent filter and collection plate changes to maintain efficiency and keep bacteria, mold, or viruses from building up within the device.

Ozone

Ozone is a natural oxidant produced in a similar fashion as organic oxidants. Like hydroxyls, it decomposes VOCs and kills mold, bacteria, and viruses. However, it does not break down as many types of VOCs as hydroxyls, and due to its very slow reaction time, high concentration levels are required. These levels are much higher than OSHA (Occupational Safety and Health Administration) safety limits, creating a toxic environment for humans. Therefore, ozone treatment can only be done in unoccupied areas. Unlike hydroxyl machines, ozone systems also have an unpleasant side effect of bleaching dyes and artwork, as well as damaging certain materials including electronics, paper, fabric and leather.

Needle Point Ionization

Needle point ionization systems, an improvement over the previous generation of ionization in the form of non-thermal plasma generators, use stainless steel needles, carbon fiber brushes and direct current to produce plasma. The ions produced in this process react with and destroy the cell walls of microbes that pass through the system. Like hydroxyl generators, they also decompose VOCs and other inorganic gases, but only as they move through the device. The air sanitation does not continue to occur outside the system as it does when hydroxyl generators start the chain reaction of organic oxidants in the indoor environment. While needle point ionization has drastically reduced the amount of ozone produced in the earlier plasma systems, there are no studies that show how uniformly the ions spread throughout the treatment zone. This makes it difficult to recommend these types of systems for larger buildings and offices as the true area effect is unclear. There are assertions that hydroxyls and superoxides are produced in needle point ionization systems, but there are no studies to back up this claim. It is clear, however, that small organic oxidation by-products such as ketones, acids, alcohols and aldehydes are produced. In the event that these substances are not destroyed as fast as they are formed, there is a risk of accumulation in the air and ultimate health concerns for those in the treatment zone.

Ultraviolet PCO Air Purifiers

Air purification systems known as ultraviolet photocatalytic oxidation (PCO) use a catalyst such as titanium oxide, which is irradiated by an ultraviolet light. This irradiation generates the production of oxidants, which react with and adsorb microbes and VOCs. PCO systems cannot produce enough oxidants to effectively treat a bigger space and were not designed for large areas. In fact, they were used by NASA for cleaning the air in the small, confined area of the shuttle. No ozone is formed in these systems, so that is not a safety concern. However, oxidation that does not get completed produces levels of formaldehyde and acetaldehyde four times higher than normal. PCOs can only handle low air speeds, limiting the volume of air it can process. They can only be used in low-humidity areas as water interferes with the catalyst’s ability to produce oxidants. This is in contrast to a hydroxyl machine, which actually performs better with humidity. A 2018 report from the EPA (Environmental Protection Agency) suggests that PCO devices “might not work as advertised” when it comes to the removal of VOCs, and that its effectiveness for use in homes is “largely undocumented.”

Ultraviolet Germicidal Irradiation

Ultraviolet germicidal irradiation (UVGI) air cleaners are systems installed in ductwork that use ultraviolet light against microbes. They fight against microorganisms that are both airborne and growing on surfaces within the ducts, including areas such as coils and drain pans. UV light has been shown effective at killing bacteria, viruses, and mold. According to an EPA analysis, UGVI systems are effective at sanitizing environments, but only if the microorganisms are exposed to the light for a sufficient length of time. They found that most of these systems do not deliver adequate doses of ultraviolet light to eliminate the microbes, and that UGVI devices alone do not appear to be effective on their own for air purification. Additionally, unlike hydroxyl generators, UGVI systems do not provide any hard surface cleansing activity outside of the ducts themselves. They also do not offer any VOC reduction.

In-Duct Hydrogen Peroxide Based Cleaner

These air purifiers are installed in a building’s ductwork. Like hydroxyl generators, they operate based on processes found in nature. In this case, the purification is inspired by atmospheric lightning. When lightning occurs naturally, its negative charge activates hydrogen peroxide molecules. This activity is reproduced within the in-duct system creating ionized hydroperoxide plasma which then is circulated through the areas using the building’s ductwork. The plasma causes small particles to stick together and drop, creating a particulate matter cleansing effect, although the system itself does not filter particles. Hydrogen peroxide based air cleaners destroy mold, bacteria and viruses within the treatment area, hard surfaces included. However, the reactivity of the ions is limited. The sanitizing effects begin to fall quickly the further away from the contaminant source, a distance of about three feet according to the manufacturer. Hydroperoxide plasma particles do not replicate themselves once in the environment like the organic oxides produced in a hydroxyl machine, so they do not have the chain-reaction effect that hydroxyl generators provide. Hydroperoxide plasma also does not decompose VOCs. VOCs are also supposed to be filtered in a peroxide based system, but it is unclear at what rate such filtration takes place. While a pleasant aroma is a stated benefit by certain proponents of peroxide-based air scrubbers, some customers reported an unpleasant smell resulting from their systems.

Other Options

Other sanitization options include chemicals and HEPA filters. Chemicals tend to be reasonably effective, but score low on safety. They can also only be applied to surfaces and don’t offer any air purification benefits. HEPA filters are very safe, are great for removing particulate matter from the air, but score lower on effectiveness for addressing biological contaminants. They also do not clean surfaces or continue cleaning the air outside the device the way hydroxyl generators do. Both chemicals and HEPA filters are very limited in their scope as far as how much area can be reasonably be cleaned. They also and require manual labor (chemicals) or regular replacement (HEPA filters). Hydroxyl generators are safe for people and their environments, kill pathogens both inside and outside the device, destroy surface pathogens, remove VOCs and odors both inside and outside the system. There are no other options on the market that offer the total package of sanitation, safety, and both air and surface sanitizing power that hydroxyl generators can provide. Now that we’ve reviewed the alternatives, let’s review the variety of sizes and uses for hydroxyl generators.

Hydroxyl Generator Options: Safe Air for Any Size Space

Hydroxyl generators are capable of providing safe, clean air for single rooms all the way up to large-scale office buildings, hospitals, and warehouses. They come in several categories that can be customized to accommodate the size of your structure, ensuring that you are getting the right amount of cleaning power for the square footage you need to cover

Contact us to discuss your portable hydroxyl generator options and get you, your guests, employees, customers, students and more breathing easier.

General Purpose

Hydroxyl generators come in several different free-standing portable sizes. The smallest units cover 100-500 square feet and weigh less than ten pounds. They move up the scale to a maximum of 3,250 square feet for the largest portable units.

Easy to Use

Regardless of size, a portable hydroxyl machine requires no installation; simply plug them in and turn them on. They don’t need calibration or programming. Portable hydroxyl generators don’t require frequent or costly maintenance; simply change the UV optic after every 9,000 hours of use. That is a little over a year if it is being run non-stop, all day, every day.

Energy Efficient

A portable hydroxyl machine is energy efficient, ranging from less than 170 watts to 230 watts, roughly the energy usage of an 8-quart slow cooker on high. The fan noise output for smaller portable units range from just above a whisper to around 40dB, or average home background noise. Some sizes output up to 55dB, just lower than normal conversation level.

Customizable

Your selection of portable hydroxyl generators can be customized to fit your space, and you can easily take them with you when you move or change office locations. They are perfect for smaller offices, school rooms, businesses and homes. A larger portable hydroxyl machine can be used for heavily contaminated areas and is easy to move from place to place for decontamination in multiple areas.

Serious Toxin Control

The largest portable hydroxyl generators have three UV optics and are capable of treating smoke, fire and flood damaged areas and zones contaminated by mold, sewage or chemical spills. These are the heavy-hitters that should be used for mitigating serious environmental toxicity.

Medical Purposes

If you need or want FDA registration for your treatment space, you’ll want our portable hydroxyl machine that is designated as a Class II medical device. It covers 130 – 500 square feet and offers all the same benefits as the other general purpose portable units.

Perfect for Health Care Environments

These hydroxyl generators are ideal for hospital rooms, waiting areas, medical and dental offices, senior centers, conferences and meeting rooms and more. They also offer peace of mind for ill, injured or immune compromised individuals recovering at home.

Peace of Mind for Businesses

Especially in today’s sanitation-conscious climate, air and surface safety is a paramount business concern even for offices that are not catering to medical needs. Storefronts and small offices boasting a hydroxyl generator that is an FDA-approved Class II medical device can feel confident that they are offering a clean, secure environment for everyone. Having a hydroxyl machine can also help ease customer concerns about disinfection and hygiene.

Energy Efficiency

These units draw 230 watts (max), a little less than an average sized warm mist humidifier. Noise levels produced from these hydroxyl generators is less than 40dB. We are available to discuss the specifics of your FDA registration requirements for air purification and how hydroxyl generators can meet your needs. Contact us today for a consultation. [link to client’s contact page]

Ready to breathe with confidence?

Contact us today for a consultation and see how hydroxyl generators can level up your organization’s health, no matter how large or small.

Fixed Solutions

If you are sold on the air and surface cleansing power of hydroxyl generators but are looking for more permanent solutions, there are two primary options: wall-mounted and in-duct. Both provide the same quality sanitation but are applied in different situations.

In-Duct Systems

In-duct hydroxyl generators are inserted into a building’s ductwork, leveraging the existing system of air circulation to spread the cleansing organic oxides throughout the entire space. Anywhere the ducts go, the hydroxyls and organic oxides will follow. A benefit of in-duct hydroxyl generators is that they can also sanitize elements within the duct system such as coils and filters, offering an even more efficient level of cleaning. Another bonus of a hydroxyl machine within a duct is that it does not contain fans, generating zero additional noise above the sound of the heating or cooling fans themselves. In-duct units are hidden away from view and won’t take up valuable space in the treatment area. There are several sizes of in-duct hydroxyl generators, serving rooms as small as 300 square feet and as large as 3000 square feet. They are specifically designed for non-stop operation and contain two hydroxyl generating optics. In-duct units are well suited for commercial, school, or hospitality use as well as office, retail, and medical settings. They require installation by an electrician and are wired to an AHU (air handling unit) or an electrical panel. An in-duct hydroxyl machine is very energy-efficient, drawing only 100 watts (nominal), about the same energy usage as a 100-watt lightbulb.

Wall-Mounted Systems

Wall-mounted hydroxyl generators are another permanent solution for air and surface cleansing. They are excellent alternatives for situations where HVAC ducts cannot be used for in-duct units. Wall-mounted units are out of the way and can provide sanitation for 3,400 to 6,500 square feet. They come with a separate control panel and require installation by a licensed electrician. However, you can also create a hybrid solution by purchasing brackets and mounting a portable unit to the wall. Wall-mounted hydroxyl generator units create a continuous stream of purified air in a specific direction (either downward or outward) once attached to the wall. Because of the large area it can treat, this type of hydroxyl generator is perfectly suited for warehouses, large commercial areas, gymnasiums, and other industrial purposes. Noise output 10 feet from the unit is 60dB, about the same level as average background music or a running air conditioner. If you’re on the fence as to whether your building needs a permanent hydroxyl generator or if it’s better suited for a portable unit, feel free to contact us for a consultation. We’ll use our specialized experience in hydroxyl generator installation to help you make the best decision for your application.

Heavy Duty Purposes

One of the big drawbacks of many other air sanitation systems is that they are very limited in the amount of space they can cover. Hydroxyl generators do not have such restrictions. With the right number of industrial-suited hydroxyl generators, you can cover vast spaces using either in-duct units or wall-mounted units, or a combination of custom devices. No matter the size of your facility, hydroxyl generators can provide a clean, safe environment for both the occupants and the materials within.

When you’re ready to take the first steps to creating a healthier workplace for your large building, call us. [link to client contact page] We specialize in custom solutions for high square footage facilities and are ready to provide you with your optimum hydroxyl generator answer.

Who Should Consider Installing a Hydroxyl Machine?

While there are hydroxyl generators to fit any size building, from homes to small offices, this air and surface sanitizing technology is uniquely suited for areas where large numbers of people tend to gather. Our response to COVID-19 has rightly improved our conscientiousness toward cleanliness and pathogen control, but it is often implemented using substances that are toxic, causing other issues.

As many businesses re-opened, they were using bleach or other harsh chemicals to wipe down surfaces, creating a situation where the air became toxic not due to viruses, but due to artificial pollutants. Even more natural cleaning solutions like those based on hydrogen peroxide were shown to contaminate the air. It is time to stop harming ourselves with our cures. A hydroxyl machine can treat air

and surface microorganisms in healthy, effective ways, making it safe to breathe again. Unlike other forms of sanitation, it doesn’t require hours of manual labor; the organic oxides do the work for us. This means that hydroxyl generators along with standard housekeeping and janitorial services will be sufficient to maintain an environment that not just looks clean, it is clean.

Large Gathering Viral and Bacterial Control

The possibilities are endless for businesses, organizations and government facilities that can benefit from hydroxyl machine technology. Think of places where large numbers of people are all together and the spread of illness is much more likely: airports and train stations, churches and other houses of worship, schools, sporting events, movie theaters, and fitness centers are just a few. Now consider places where clean air and surfaces matter even more, where biological threats either abound or those in the facility are especially vulnerable to pathogens: hospitals, nursing homes, day care centers filled with babies and toddlers, and pharmaceutical labs are all exceptional candidates for the benefits of hydroxyl generators.

Toxic VOC Control

In addition to the elimination of viruses, bacteria, and mold, don’t forget that the organic oxides produced by a hydroxyl machine also break down harmful VOCs. If you’ve ever been around new construction of any type, remodeled or refurbished areas you know the odor that is often in the area when VOCs are present. This makes hydroxyl generators the perfect addition to work sites, factories, industrial or chemical plants or new homes where the off-gassing of VOCs is a constant or immediate threat. Why not take that toxin and turn it into a member of your cleaning staff?

Specific Environmental Threats

In addition to the elimination of viruses, bacteria, and mold, don’t forget that the organic oxides produced by a hydroxyl machine also break down harmful VOCs. If you’ve ever been around new construction of any type, remodeled or refurbished areas you know the odor that is often in the area when VOCs are present. This makes hydroxyl generators the perfect addition to work sites, factories, industrial or chemical plants or new homes where the off-gassing of VOCs is a constant or immediate threat. Why not take that toxin and turn it into a member of your cleaning staff? Imagine shopping centers, convention centers, hotels, office buildings, restaurants and bars, air planes and public transportation systems all using hydroxyl generators to purify their air and surfaces. While we may not be able to ever completely eliminate pathogen risk from viruses, bacteria, and other microorganisms, we can use nature’s way to knock them out as much as possible indoors. Using hydroxyl machine technology, we can reduce the risk to everyone, and do it in a safe, efficient, effective manner.

Hydroxyl Generator Installation and Custom Hydroxyl Generator Design

If your space is larger than can be covered by portable units or if you want your hydroxyl generator to be out of the way no matter what size space you’re purifying, you’ll need someone to install the units for you, either in-duct or wall-mounted. If you have a more complicated structure, you’ll want to consult with our professional custom hydroxyl generator design specialists to create the ideal system for your facility. Here’s what you should expect from a knowledgeable consultant.

Education and Training

A professional custom hydroxyl generator installer should have thorough and up-to-date training. This includes education on personal safety, handling of infectious materials and PPE (personal protection equipment), accidental exposure response, and emergency procedures. They should also be up to date on OSHA and CDC guidelines. The right technician will also have training from the hydroxyl generator manufacturer and be able to install, calibrate, test and perform maintenance on all devices. They should be able to provide evidence of training and certifications if asked. All of our hydroxyl generator design and installation professionals check all these boxes along with having extensive experience designing custom solutions.

Thorough Analysis of Needs

When creating a custom solution, a properly experienced contractor will review the specific needs of the business or organization and get very clear on the results expected from hydroxyl generator installation. They will clearly define what healthy indoor air quality should be and what levels are ideal for the facility’s occupants. A detailed consultation will include testing if requested, to determine current levels of mold, bacteria, ozone, viruses, radon, etc. It will be determined if any levels are dangerous or of particular concern in certain areas of the building. Your ongoing needs for testing or maintenance will be clarified. The tech will also get a clear understanding of any clean air or health certifications that your building needs and help you achieve those goals. Our professionals are proud to put our customers’ needs at the forefront of the consultation and ensure a clear understanding of each organization’s unique situation.

Individualized, Structure-Specific Solutions

Your hydroxyl generator professional should take time to make an exhaustive examination of the structure to be sanitized. It’s not just about square footage; number of rooms, placement of vents, ceiling heights, typical and max occupancy, and presence of plants and animals are also part of the design process. When designing your custom solution, they should take into consideration the age, condition, design and capabilities of the HVAC equipment, ducts, and the building as a whole. Condition and volume of hard and soft surfaces, potential infection rates for biological threats, and HVAC programming are also factors that go into a building’s hydroxyl machine design.

After analyzing all the factors, hydroxyl generator installation experts will create and implement a plan of action. They will ensure the placement of units for maximum efficacy and advise on modification of vents if needed. If changes are needed to ensure proper air flow, ventilation and particulate removal, recommendations will be made and implemented according to your building’s needs. Our techs are experienced, professional and dedicated to giving your facility the cleanest, safest and healthiest air possible.

Hydroxyl Machine Technology: Safe, Pure Air for Today

If the proliferation of COVID-19 has shown today’s businesses anything, it is the need for a clean environment. Employees and customers need to feel at ease for business to resume as usual. A significant part of that peace of mind is knowing that air and surfaces are free from harmful biological elements as well as non-living toxins. As we move into the future, businesses, schools and other organizations that prioritize healthy environments will be the most successful. People don’t just want you to care, they want you to show it.

With hydroxyl generator technology keeping your air and surface contaminants under control at all times, you can provide that peace and safety we all need. With the demonstrated capability to clean and disinfect without manual labor or harsh chemicals, hydroxyl generators provide returns that go far beyond merely a clean environment. They could be the best answer to how we return to life, creating a healthier, cleaner post-pandemic world, fueled by the power of the sun.

Don’t wait to get started on your journey to safe, pure air. Contact us today to discuss the best hydroxyl generator system for your indoor areas. Let’s return to good health together.